Air-Mods typically takes-on about one shop project a year. We consider a shop project an aircraft project that requires major reconstruction and, most often, one that we can work on as time allows (i.e. – without a set deadline). By major reconstruction, that usually means that one or two of the major components (fuselage, empennage, or wing) have to be swapped-out from other airplanes or rebuilt from new or fabricated parts.

Air-Mods typically takes-on about one shop project a year. We consider a shop project an aircraft project that requires major reconstruction and, most often, one that we can work on as time allows (i.e. – without a set deadline). By major reconstruction, that usually means that one or two of the major components (fuselage, empennage, or wing) have to be swapped-out from other airplanes or rebuilt from new or fabricated parts.

We enjoy this work for a couple of reasons. First, we enjoy the pride in bringing an aircraft back to life from parts from other airplanes. Like most pilots, we hate to see an airplane abandoned or scrapped. Second, because this work keeps us knowledgable on the engineering that goes into the manufacturing of the aircraft – which strengthens our skillsets when performing maintenance and even pre-buy inspections during our day-to-day operations.

This work is labor intensive and requires specialized expertise and equipment, such as wing jigs and sheet metal fabrication machines, in order to do it right. As such, we are one the few shops on the east coast that can take-on this type of work and, more importantly, can do this work with the quality that matches the original manufacturing standards. As an example, we’re one of the few shops in the country that can replace wing spar caps on a Mooney and, moreover, with the wing still joined to the fuselage – saving time and related expense for the customer.

Sometimes customers bring these project to us, and sometimes we just stumble upon them. But it just seems to work out that we have one in the works at any given time. Project in the past have included:

- Mooney M20K / 252: airplane was totalled in an off-airport gear-up landing (occupants were OK). We joined the aft fuselage and empennage to the forward fuselage, overhauled the engine, installed a new prop, new interior, and new avionics.

- Mooney M20J / 201: airplane wing was severely damaged, but not totalled (occupants were OK). We replaced the wing from a "M20K", installed the landing gear, gear doors, and control surfaces.

- Piper PA 160 / Warrior – hangar accident which caused structural damage to the empannage resulting in the insurance company totalling the airplane. We refrabricated the structural members of the tail section, fabricated and installed new sheet metal, and painted to match the existing paint scheme.

- And the list goes on….

These airplane continues to fly today and the owners are quite pleased with the results!

Our current shop project we’re starting in September, 2010 is a 1978 Mooney M20J/201. Due to water contamination in the fuel, the airplane suffered an off-airport landing shortly after take-off. The pilot was OK, the mid-time engine and prop were also OK, but the airplane was totalled. The wings did not separate from the fuselage, and as you can see, the cabin is in very good condition – both testimony to the strength of the Mooney structural design!

Our current shop project we’re starting in September, 2010 is a 1978 Mooney M20J/201. Due to water contamination in the fuel, the airplane suffered an off-airport landing shortly after take-off. The pilot was OK, the mid-time engine and prop were also OK, but the airplane was totalled. The wings did not separate from the fuselage, and as you can see, the cabin is in very good condition – both testimony to the strength of the Mooney structural design!

Stats & Features:

- Total time on airframe: 2700

- SMOH: 835 Prop: 772

- Low Profile Main Gear Doors

- Overlapping Nose Gear Doors

- Single-piece Fiberglass Belly

- Thick windows

As of late October 2010, we’ve painted the wing and getting ready to reassemble the components. Purchase price at this point is $42,000.

(Click to enlarge)

As of November 7, 2010, we’ve reinstalled the landing gear into the wing, rejoined a tail cone to the cabin, mounted the fuselage onto the wing, and attached the tail assembly. Purchase price at this point is $49,000.

(Click to enlarge)

As of November 13, 2010, we’ve painted the fuselage with the base white coat of paint and applied the masking for the trim scheme. Purchase price at this point is $54,000.

(Click to enlarge)

Here’s Shane applying wing root tape prior to reinstalling the wing root fillet.

(Click to shrink Shane – we don’t want to enlarge him more – he’s already too proud of his paint-job)

As of November 16, 2010, we’ve painted the fuselage with the blue trim paint (it looks really good!). Purchase price at this point is $59,000.

(Click to enlarge)

As of January 12, 2011, we’ve hung the engine, replaced hoses as necessary, and are ready to flush the engine, add oil and fuel.

As of January 12, 2011, we’ve hung the engine, replaced hoses as necessary, and are ready to flush the engine, add oil and fuel.

We’ve finished painting the cowl, belly pan, gear doors, and control surfaces.

We also reinstalled and adjusted the gear doors and then conducted multiple gear retraction cycles to assure that the landing gear is working properly.

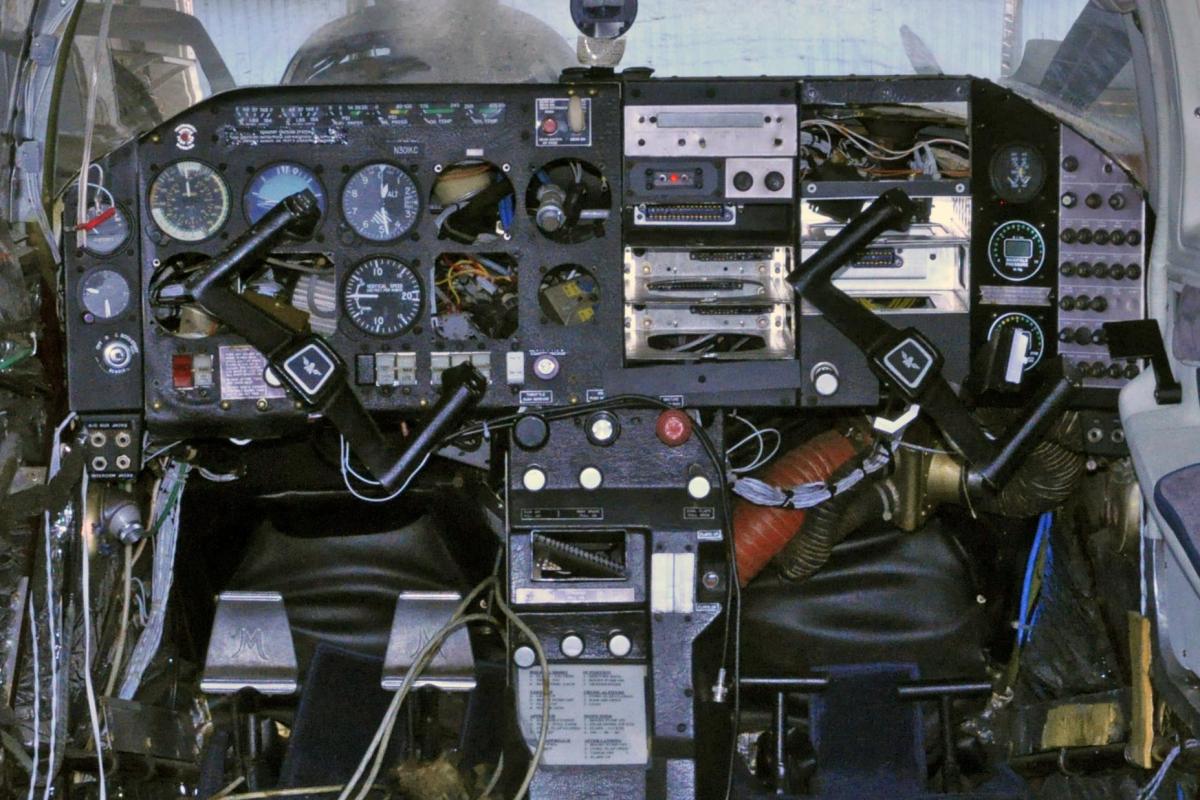

As of January 12th, Matt has fabricated a new custom panel, reinstalled the avionics, and applied the appropriate placards. Here’s the before and after photos:

| Before | After |

|

|

| Click to enlarge | Click to enlarge |

|

After, After… |

|

|

|

| Click to enlarge | |

| The Panel Includes: | Other Features |

|

|

As is typical of our own shop projects, we can only work on them as time permits. This has certainly been the case with N301KC. We’ve been pretty busy with customer airplanes since January and have found only a few hours here and there to work on it. After selling our M20C in early October, which was a favorite by quite a few of our rental customers, we became more motivated to finish the shop project so we’d have another Mooney on the flight line. So, in October, we test-ran the engine, painted the cowl, reinstalled the interior and the remaining control surfaces, and updated the paperwork.

Shane, who led this project, was ready to take N301KC for some ground tests on Friday, October 28th. Accompanied by Aimee Mendoza, one of our flight instructors, the two of them performed an extended run-up and several high-speed taxis in preparation for the upcoming maiden flight.

We had been itching to take N301KC for it’s maident flight, but between work, business travel, and the weather, we just couldn’t find a time over the last month for Shane and me to fly it. After a rainy day on November 23rd (just before Thanksgiving), the weather started to clear at about 4:30 pm so Shane and I grabbed our headsets, preflighted the airplane, and climbed in for the maiden flight.

In the end, the airplane turned-out much better than expected…due in part to the fact that we invested more than expected. As we got deeper into the project, we made the decision to invest more in materials and workmanship to round it out with the finishing touches we would want in our own personal airplane. So, if you are interested in buying it, the current price is now $79,900 – just slightly more than our original mid-seventies estimate. If you’re interested in renting it, look for it as the newest addition to our rental fleet soon. You’ll love how it looks and flies!

Dave